Additive manufacturing as a game changer for future-oriented electrochemical energy conversion and storage

Project description

The new research project entitled „Additive manufacturing as a game changer for future-oriented electrochemical energy conversion and storage” started on 1 January 2025. The Montanuniversitaet Leoben, represented by the Chair of Physical Chemistry and the Chair of Structural and Functional Ceramics, is collaborating with the Vienna company Lithoz GmbH, the global market leader in ceramic 3D printing, on new methods for the production and characterization of high-temperature fuel cells and electrolysis cells. The core of the project is the development of innovative manufacturing methods and novel materials for a paradigm shift in cell design, which will contribute to increasing power density, reliability, and service life, reducing manufacturing costs, and achieving independence from critical raw materials. The project is funded by the Austrian Research Promotion Agency (FFG) within the framework of the 2023 Energy Research Programme (e!MISSION).

Additive manufacturing as an enabler for sustainable ceramic manufacturing

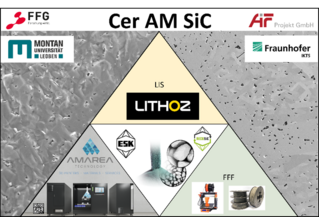

New Project CeramSIC - Intro

The aim of the project CeramSiC is to manufacture complex components from SSiC with a particularly high level of mechanical, chemical, and thermal resistance and high sintering density using various AM methods in a close-to-shape and resource-efficient manner.

The central element here is the use of recycled SiC powder to significantly reduce CO2 emissions during powder production and optimize thermal processing.

Based on the independent development work of the project partners, three additive processes are being considered for the production of SSiC due to their characteristics: laser-induced slip casting (LIS), multi-material jetting (MMJ), and fused filament fabrication (FFF). All three processes are based on the processing of SiC powders, which must be characterized by good processability, high purity, and a defined grain size distribution. Likewise, all three processes are linked to downstream thermal processing in order to produce components made of pressure less sintered SiC from the semi-finished product through a debinding and sintering step.

Publication on Plasma Wire Arc Manufacturing Process

Thermo mechanical Finite Element Analysis of the plasma Wire Arc Additive Manufacturing process in DEFORM® 13,

Marcel Czipin, Alexander Wenda, Karin Hartl, Emre Akalin, Martin Stockinger

Journal of Advanced Joining Processes, Volume 12, 2025, 100321, ISSN 2666-3309,

doi.org/10.1016/j.jajp.2025.100321

(https://www.sciencedirect.com/science/article/pii/S2666330925000421)

Keywords: Wire Arc Additive Manufacturing; Finite Element Analysis; DEFORM®; Ti–6Al–4V; Grain growth

NEW WAAM Lab

At the Chair of Metall Forming, a cutting-edge lab for Wire Arc Additive Manufacturing (WAAM) has been established. The Cyber-Physical Robot Cell for WAAM conducts process studies and develops optimal parameter sets. A physically assisted AI approach supports experimental work to build in-depth process knowledge. Further Reading